PSoc62™开发板之ADC读取电压

实验目的

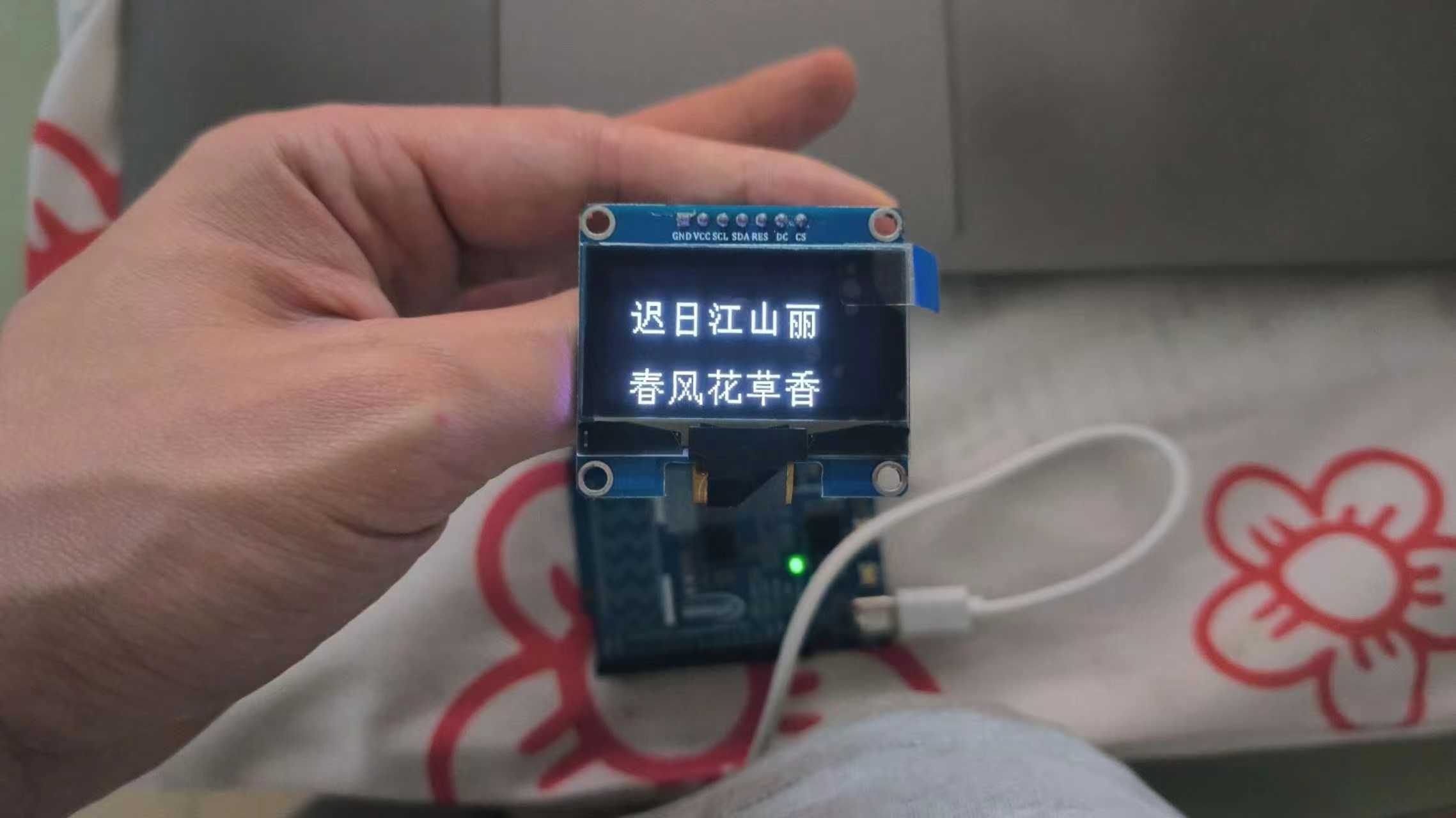

2.使用OLED显示电压值

实验准备

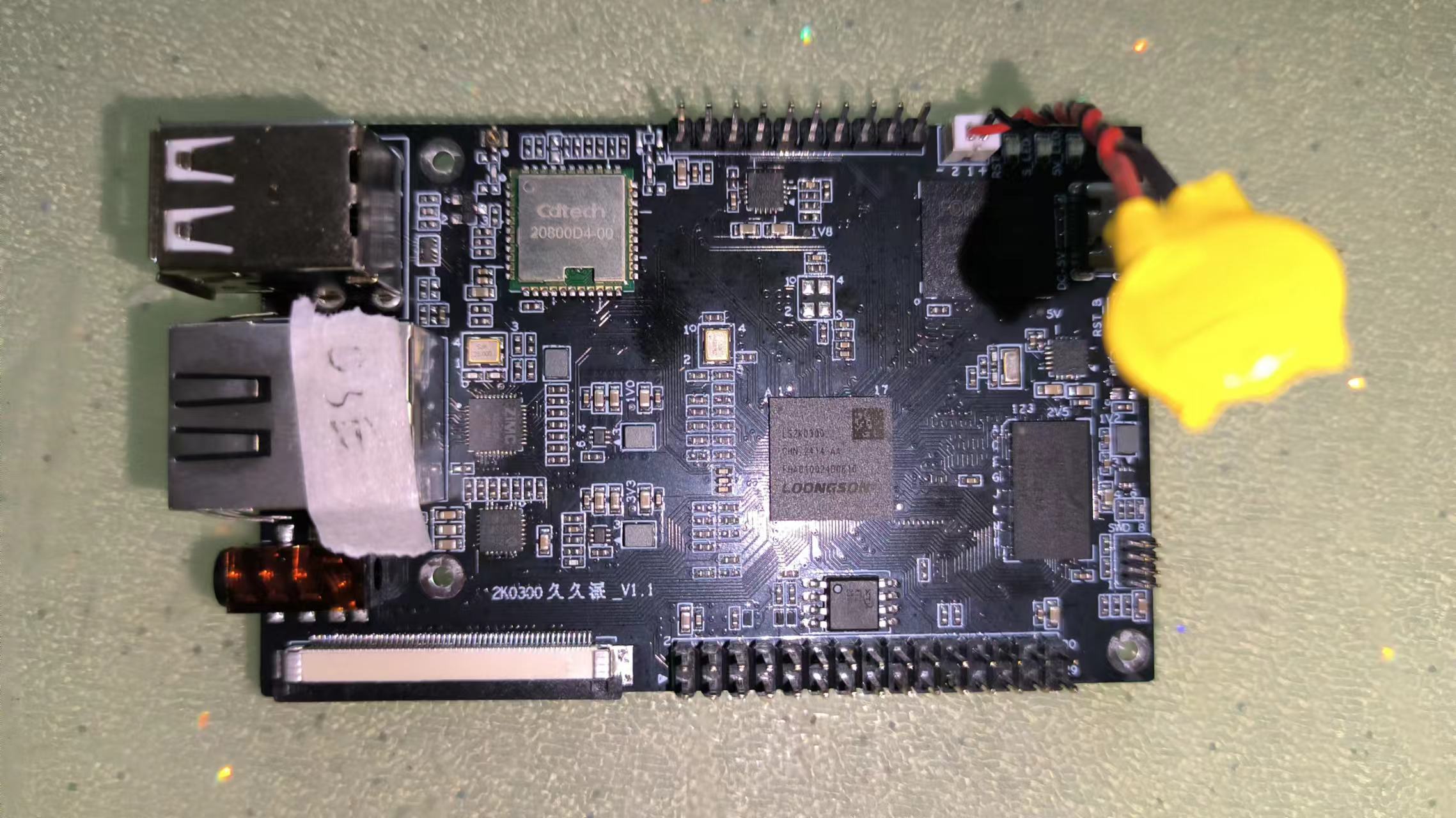

- PSoc62™开发板

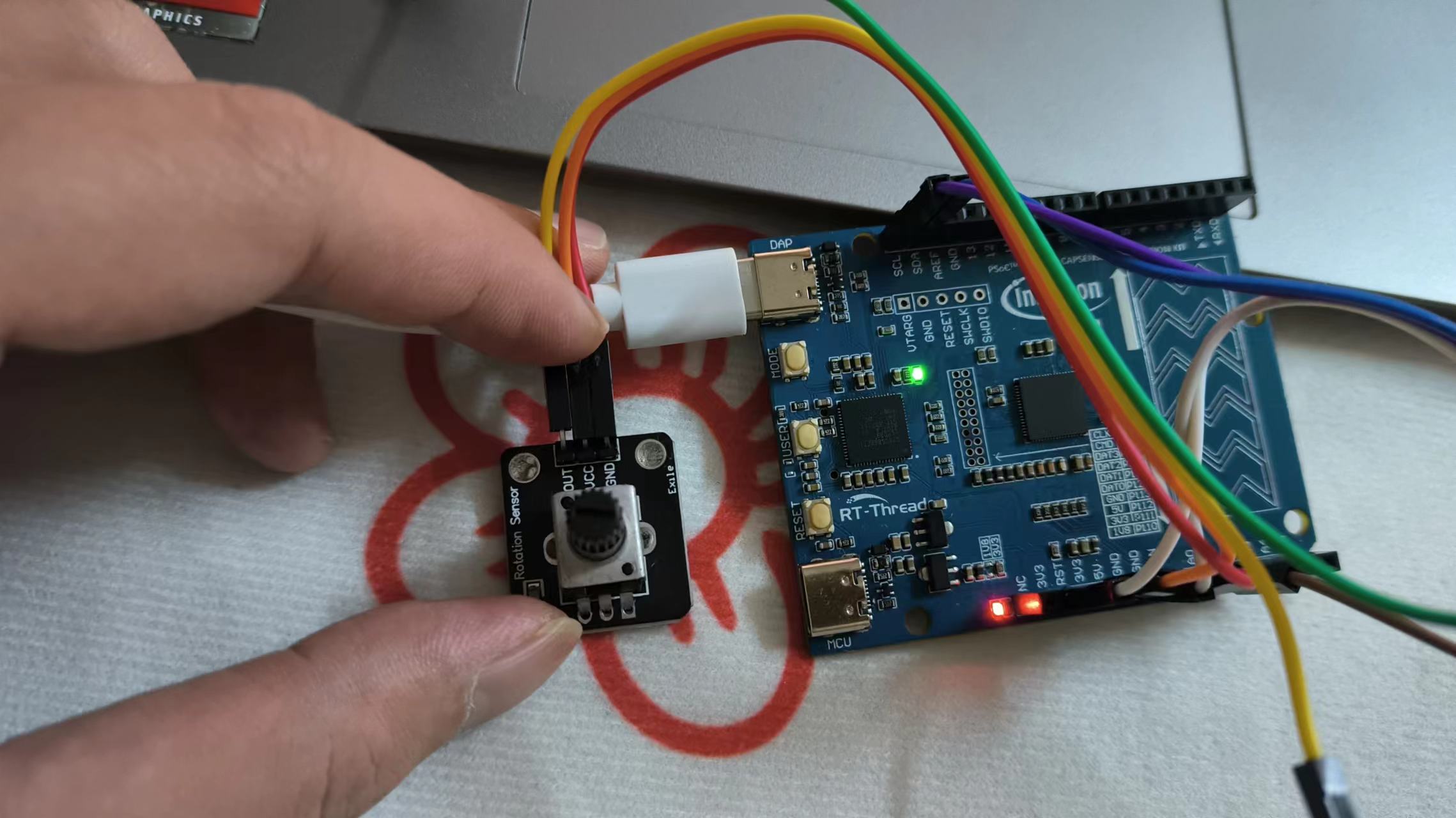

- 电位器

- SSD1306 OLED模块

- 公母头杜邦线

组件配置

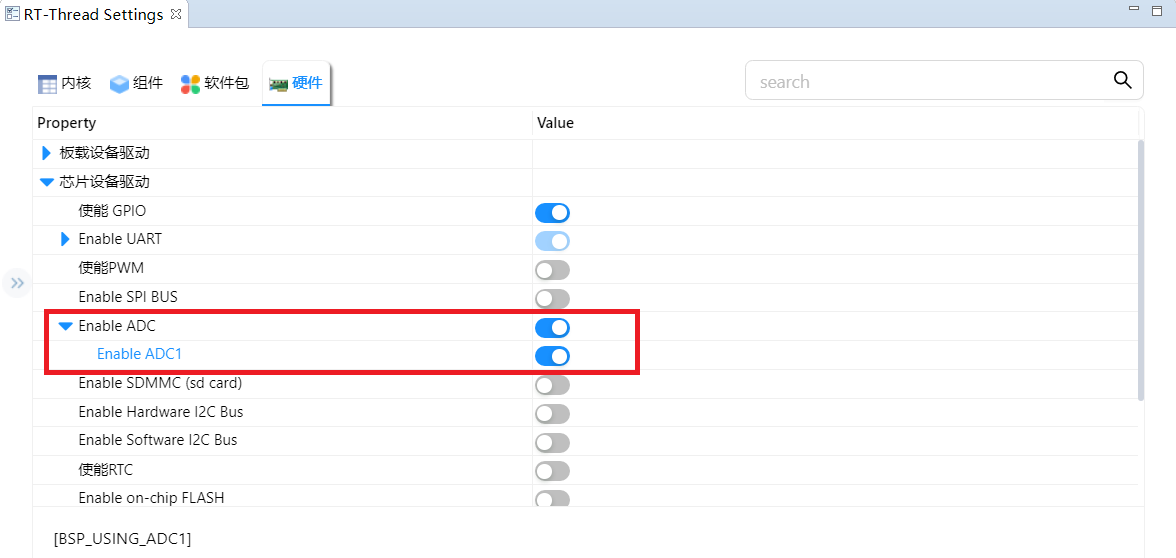

ADC配置

RT-Thread的HAL层目前只适配了ADC1,在RT-Thread Settings里边只能看到一个选项,我们把它开启了

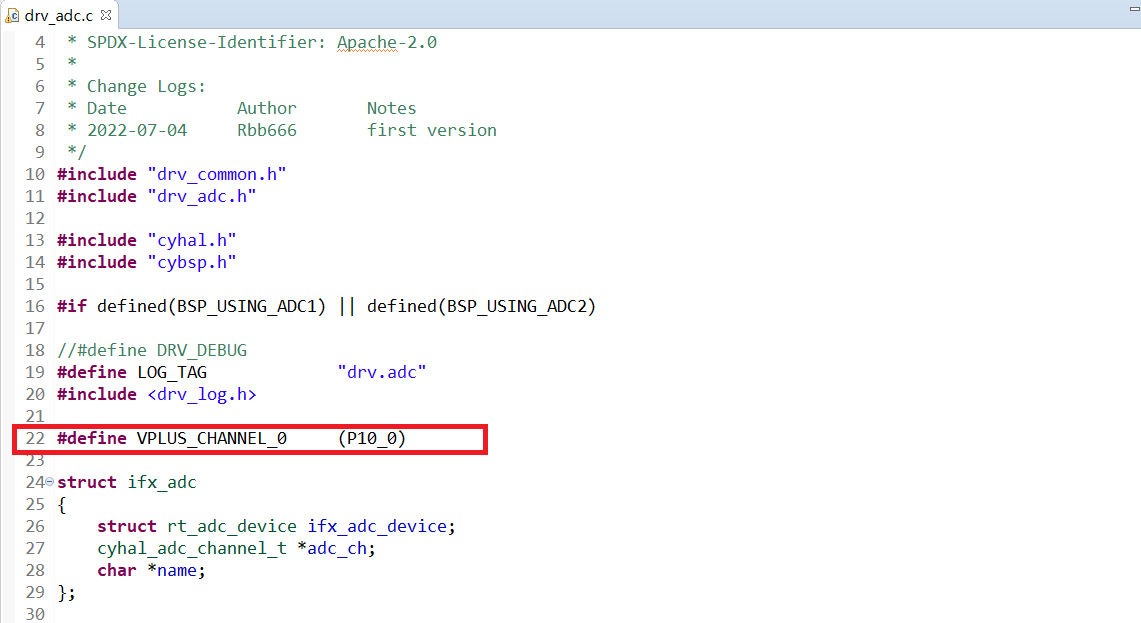

打开libraries/HAL_Drivers/drv_adc.c文件,发现ADC1对应的GPIO为P10.0

OLED配置

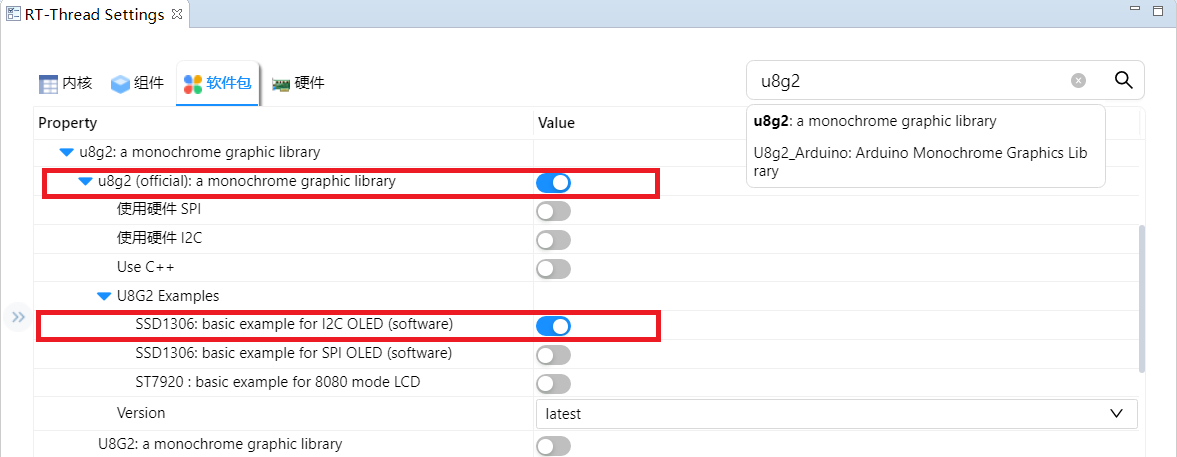

OLED模块的主控是ssd1306,需要在RT-Thread Settings里边使能u8g2软件包,这里使用软件的方式模拟i2c时序

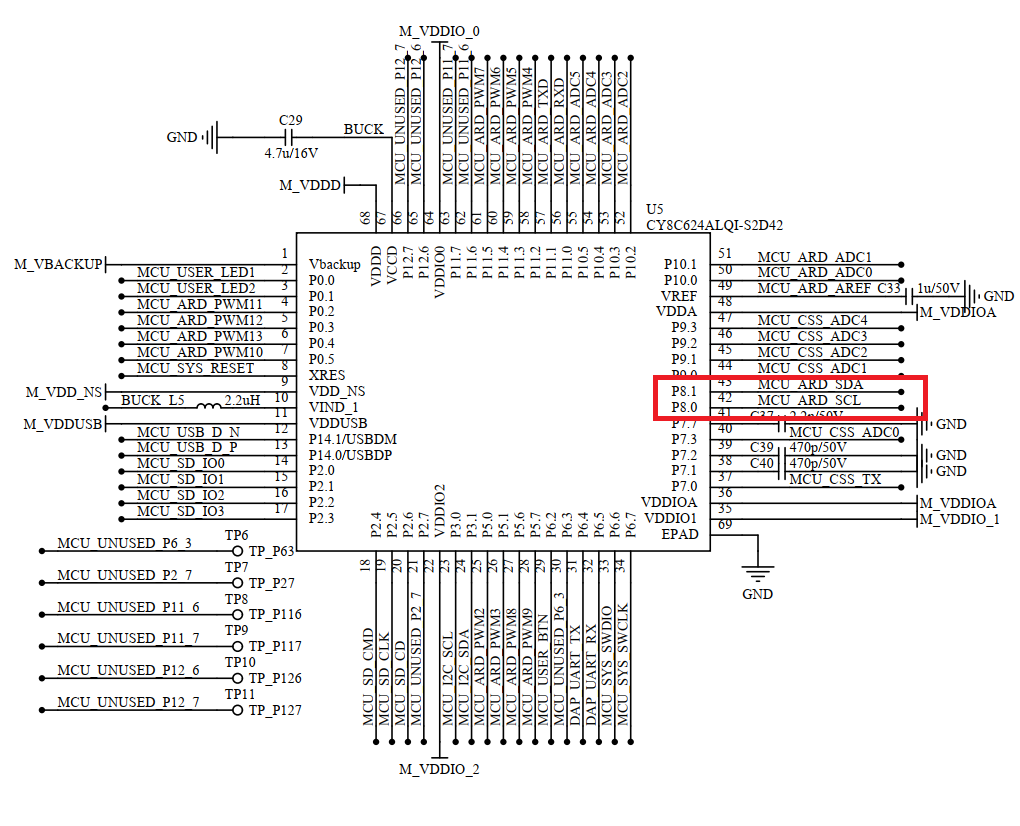

注意要在代码里边绑定i2c引脚,pin number和GPIO的对应关系:P8.0 : 8 x 8 = 64,P8.1 : 8 x 8 + 1 = 65

#define OLED_I2C_PIN_SCL 64 // P8.0

#define OLED_I2C_PIN_SDA 65 // P8.1模块电路

OLED

MCU_ARD_SCL对应P8.0

MCU_ARD_SDA 对应P8.1

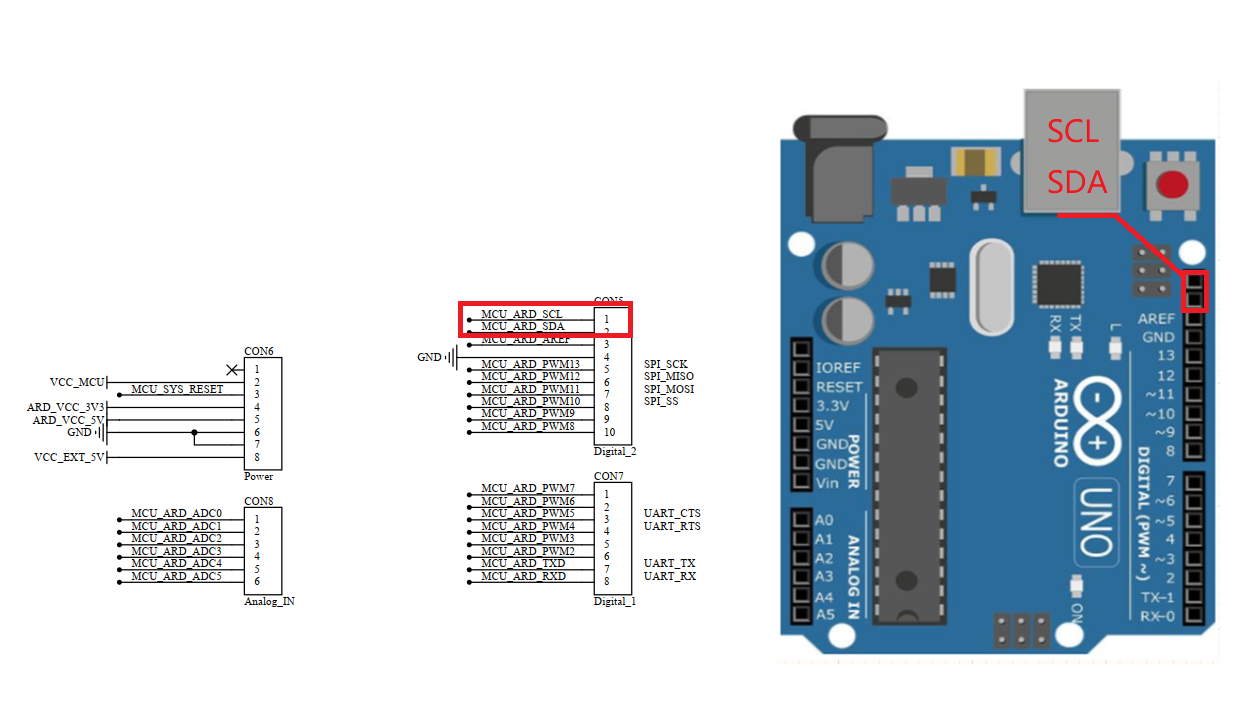

右侧排母从上往下第1、2引脚分别对应SCL、SDA

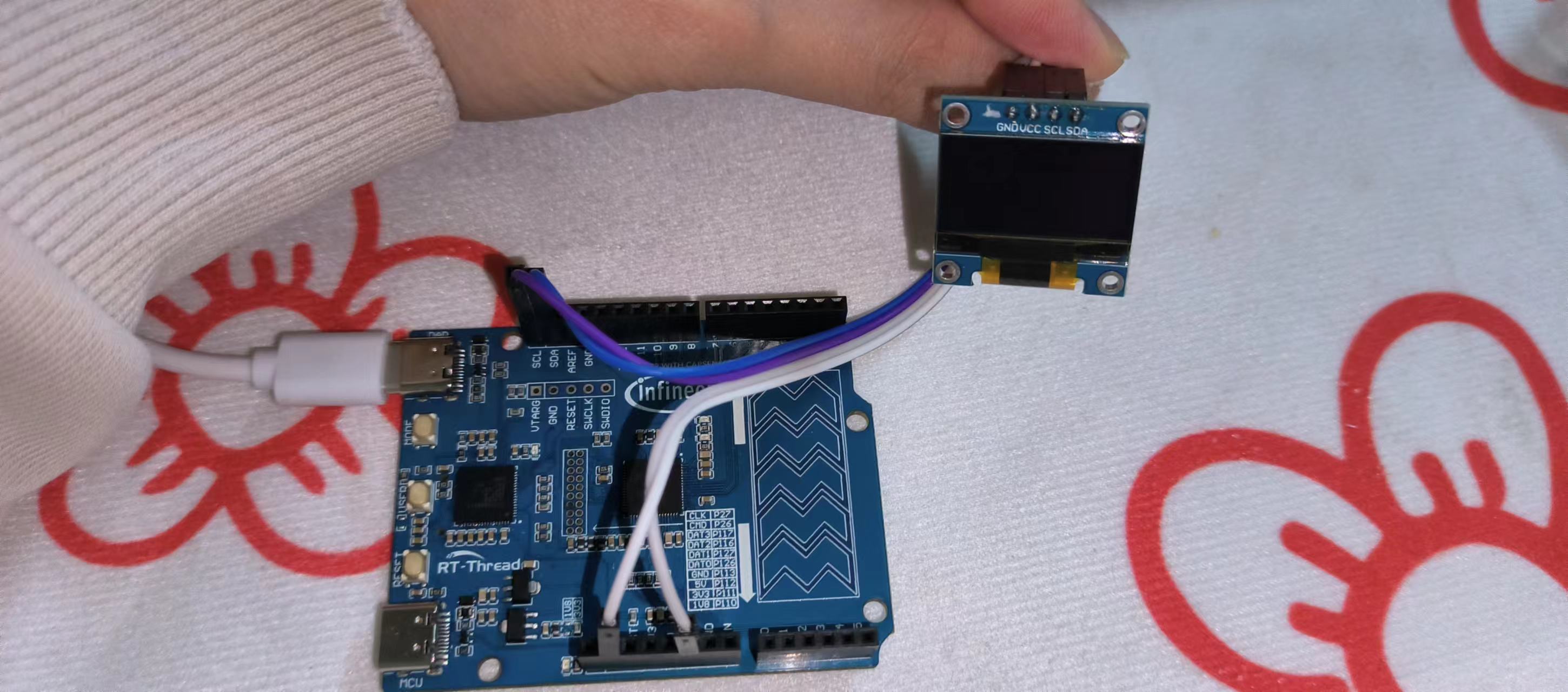

依次连接OLED模块的VCC、GND、SDL、SDA引脚

电位器

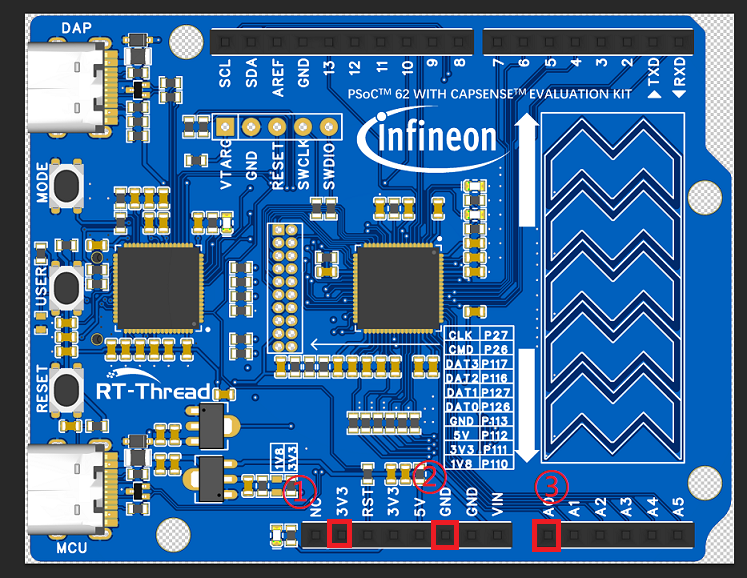

下图中的①、②、③引脚分别连接电位器的VCC、GND、OUT引脚,③即A0代表P10.0

程序设计

由于RT-Thread给PSoc62™适配的ADC驱动有一些问题,这里需要修改一下电压获取接口,打开libraries/HAL_Drivers/drv_adc.c文件,修改函数ifx_get_adc_value的实现:用cyhal_adc_read_uv接口替代cyhal_adc_read

#define MICRO_TO_MILLI_CONV_RATIO (1000u)

static rt_err_t ifx_get_adc_value(struct rt_adc_device *device, rt_uint32_t channel, rt_uint32_t *value)

{

cyhal_adc_channel_t *adc_ch;

RT_ASSERT(device != RT_NULL);

adc_ch = device->parent.user_data;

channel = adc_ch->channel_idx;

#if 1

*value = cyhal_adc_read_uv(adc_ch) / MICRO_TO_MILLI_CONV_RATIO;

#else

*value = cyhal_adc_read(adc_ch);

#endif

return RT_EOK;

}OLED初始化

// OLED

u8g2_t u8g2;

char buffer[50];

u8g2_Setup_ssd1306_i2c_128x64_noname_f( &u8g2, U8G2_R0, u8x8_byte_sw_i2c, u8x8_gpio_and_delay_rtthread);

u8x8_SetPin(u8g2_GetU8x8(&u8g2), U8X8_PIN_I2C_CLOCK, OLED_I2C_PIN_SCL);

u8x8_SetPin(u8g2_GetU8x8(&u8g2), U8X8_PIN_I2C_DATA, OLED_I2C_PIN_SDA);

u8g2_InitDisplay(&u8g2);

u8g2_SetPowerSave(&u8g2, 0);ADC1初始化

// ADC1

rt_adc_device_t adc_dev;

rt_uint32_t value;

rt_err_t ret = RT_EOK;

adc_dev = (rt_adc_device_t)rt_device_find(ADC_DEV_NAME);

if (adc_dev == RT_NULL)

{

rt_kprintf("adc sample run failed! can't find %s device!\n", ADC_DEV_NAME);

}

ret = rt_adc_enable(adc_dev, ADC_DEV_CHANNEL);

if(ret == RT_EOK)

{

rt_kprintf("adc sample run success! find %s device!\n", ADC_DEV_NAME);

}整合代码

#include <rtthread.h>

#include <rtdbg.h>

#include <board.h>

#include <rtdevice.h>

#include <u8g2_port.h>

#define OLED_I2C_PIN_SCL 64 // P8.0

#define OLED_I2C_PIN_SDA 65 // P8.1

#define ADC_DEV_NAME "adc1"

#define ADC_DEV_CHANNEL 0

int main(void)

{

// OLED

u8g2_t u8g2;

char buffer[50];

u8g2_Setup_ssd1306_i2c_128x64_noname_f( &u8g2, U8G2_R0, u8x8_byte_sw_i2c, u8x8_gpio_and_delay_rtthread);

u8x8_SetPin(u8g2_GetU8x8(&u8g2), U8X8_PIN_I2C_CLOCK, OLED_I2C_PIN_SCL);

u8x8_SetPin(u8g2_GetU8x8(&u8g2), U8X8_PIN_I2C_DATA, OLED_I2C_PIN_SDA);

u8g2_InitDisplay(&u8g2);

u8g2_SetPowerSave(&u8g2, 0);

// ADC1

rt_adc_device_t adc_dev;

rt_uint32_t value;

rt_err_t ret = RT_EOK;

adc_dev = (rt_adc_device_t)rt_device_find(ADC_DEV_NAME);

if (adc_dev == RT_NULL)

{

rt_kprintf("adc sample run failed! can't find %s device!\n", ADC_DEV_NAME);

}

/* 使能设备 */

ret = rt_adc_enable(adc_dev, ADC_DEV_CHANNEL);

if(ret == RT_EOK)

{

rt_kprintf("adc sample run success! find %s device!\n", ADC_DEV_NAME);

}

while(1)

{

// read adc value

value = rt_adc_read(adc_dev, ADC_DEV_CHANNEL);

memset(buffer, 0, 50);

if(4294965 <= value) value = 0;

snprintf(buffer, 50, "Voltage : %d.%02dV\n", value / 1000, value % 1000);

// display on OLED

u8g2_ClearBuffer(&u8g2);

u8g2_SetFont(&u8g2, u8g2_font_ncenB08_tr);

u8g2_DrawStr(&u8g2, 20, 36, buffer);

u8g2_SendBuffer(&u8g2);

cyhal_system_delay_ms(200);

}

return 0;

}

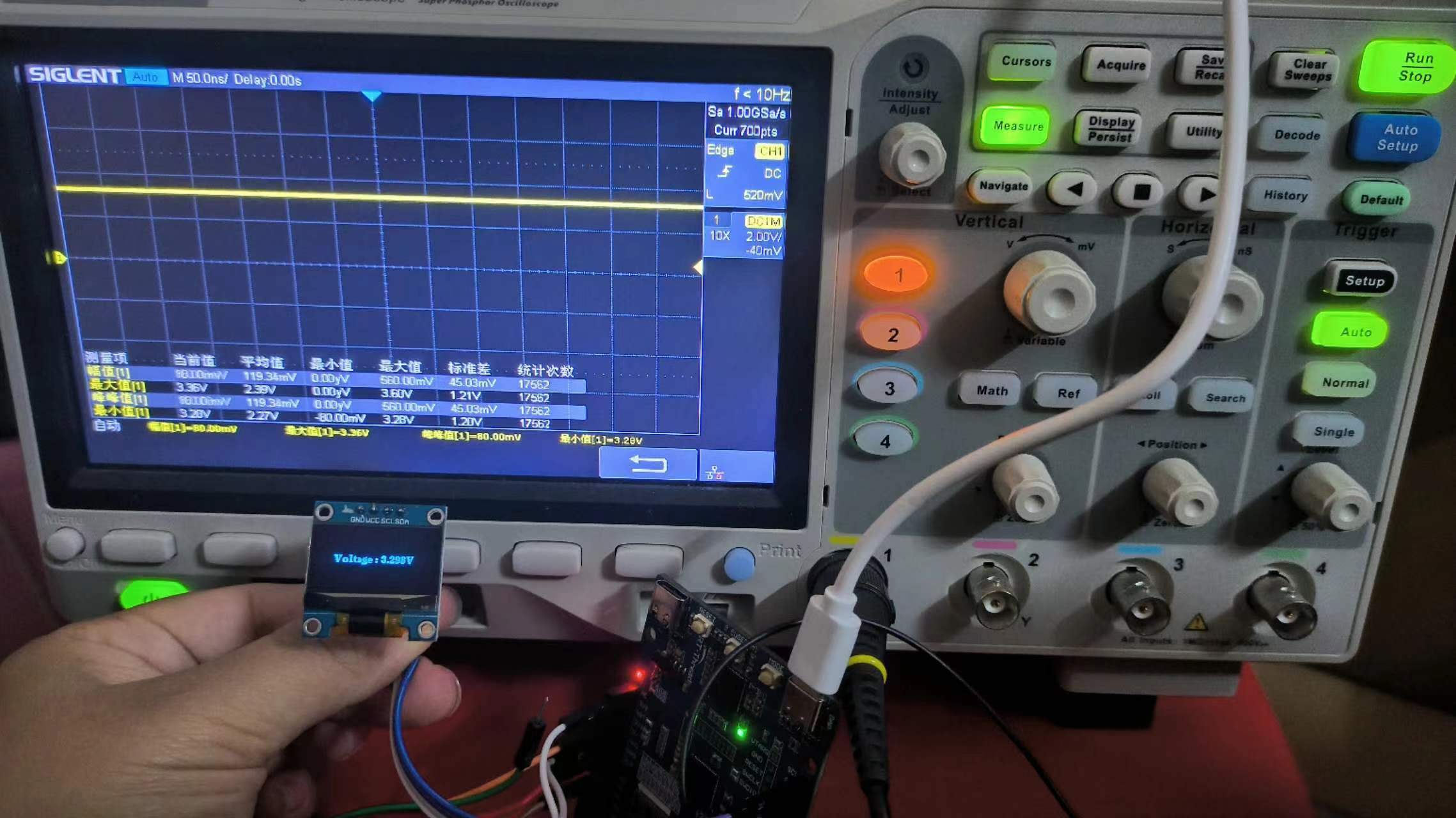

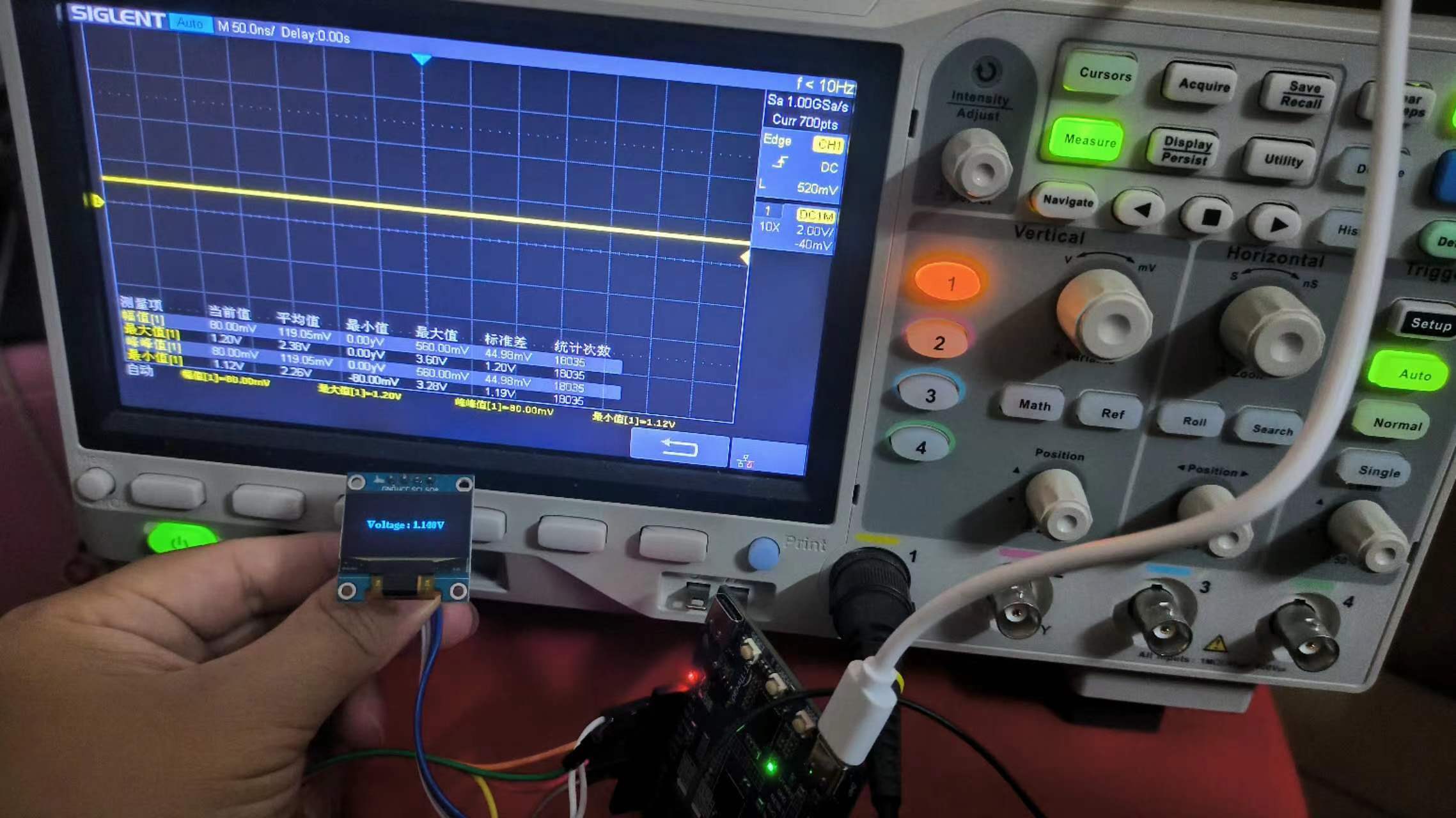

实验效果

使用示波器查看电位器不同旋转位置时的输出电压值,和OLED显示的ADC1电压值做比较,3.3V和1.1V的数值基本吻合

3.3V测量结果

1.1V测量结果

阅读剩余

版权声明:

作者:hywing

链接:https://iotstuff.cn/psoc62-mcu-adc/

文章版权归作者所有,未经允许请勿转载。

THE END